In industrial automation applications, the industrial control monitor is a key device. It not only displays relevant data, but also controls the entire industrial equipment, so it must have accurate HD technology to ensure the stability and safety of the equipment. How to buy the right industrial control monitor for you? In this article, we will provide you with a comprehensive shopping guide.

First, what are the characteristics of accuracy?

Accuracy is one of the most important features of industrial control monitors. In the process of industrial automation, the responsiveness and accuracy of the equipment is very important. Since differences in accuracy can lead to serious operational problems, it is important to make sure that an industrial control monitor has a high degree of accuracy when purchasing it. This means that the monitor must have the following:

1. High refresh rate: the higher the refresh rate of the monitor, the faster the image is updated. This means that the display can better support the accuracy and speed required in industrial automation processes.

2. Fast Response Time: The response time is the time it takes for the monitor to display the screen from the signal it receives. In a high-speed industrial automation environment, the response time must be fast to ensure that the next action of the equipment can be executed in a timely manner and maintain accuracy.

3. High precision: the higher the pixel density, the clearer the image. In the industrial automation environment, high-definition images for the normal operation of equipment is essential.

Second, how to realize the high-definition technology of industrial control monitors?

The high-definition technology of industrial control monitors involves a number of aspects.

1. Resolution: the higher the resolution of the industrial control monitor, the clearer the displayed image will be. Typically, for industrial automation applications, a resolution of 1920 x 1080 or higher is required.

2. Viewing Angle: Viewing angle refers to the viewing range that an industrial monitor can provide. Typically, for industrial automation applications, a viewing angle of 178 degrees or higher is required to ensure that each work area is adequately covered.

3. Color Depth: Color depth refers to the number of colors that the monitor can render. Typically, industrial monitors need to have 16.7M or higher color depth.tions in different environments.

Third, how to buy industrial control monitors for industrial automation?

When shopping for an industrial monitor, please consider the following aspects.

1. The size of the monitor: according to the requirements of industrial automation applications, select the appropriate size. Typically, industrial automation applications require a monitor size between 17 inches and 22 inches.

2. Durability: industrial control monitors must be highly durable in order to be used in harsh industrial automation environments and to ensure the long-term stability of the device.

3. Protection level: The protection level refers to the ability of the device to resist the external environment. When purchasing an industrial monitor, please make sure that its protection level can meet your required usage environment and ensure the long-term stability of the device.

4. Connection interface: according to the required signal source and controller to select the appropriate connection interface, so that the industrial control monitor can be quickly connected and run correctly.

Fourth, what is the role of industrial control monitor protection level of industrial equipment?

In the industrial automation application environment, industrial control monitors must have sufficient protection level to protect it from external environmental damage. Specifically, the protection level represents the safety level of the equipment. Protection ratings include IP65, IP67, etc., and represent the device's ability to protect against splashing liquids, dust, debris, and even underwater drilling. When shopping for industrial automation equipment, make sure it has an adequate protection rating to ensure stable operation.

Fifth, what are the differences in the application scenarios of industrial control monitors in different industries?

In industrial automation applications, industrial control monitors are used in a wide range of application scenarios. Typically, they are widely used in the following areas:

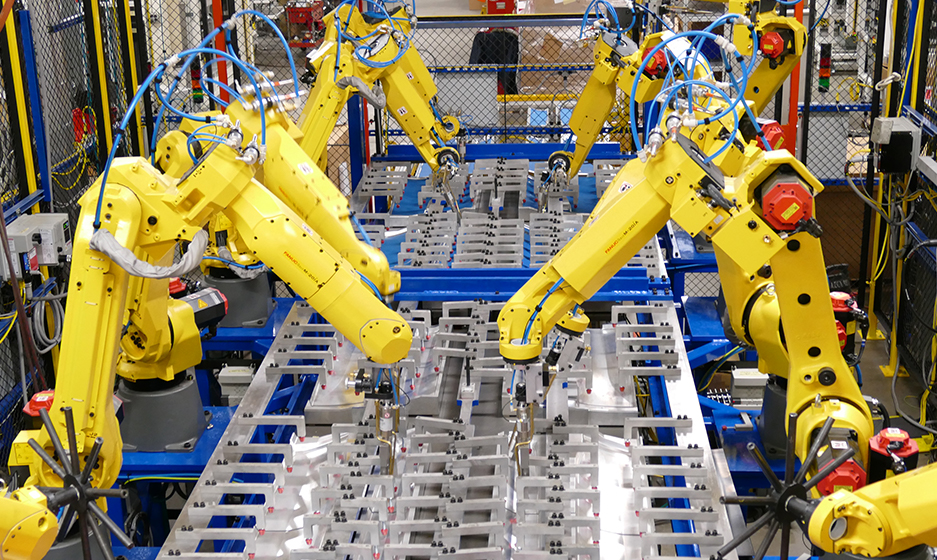

1. Manufacturing: Industrial Control Monitors can provide a precise visual interface for work, making the manufacturing process safer and more efficient.

2. Healthcare: In the field of healthcare, industrial control monitors can provide precise operating systems to help doctors diagnose conditions quickly and accurately.

3. alarm system: industrial automation applications in the environment of the alarm system needs to be accurate, the accuracy of the display can better meet the needs of these applications.

In short, industrial control monitors in industrial automation application environments must have the advantages of high accuracy and HD technology. When purchasing an industrial monitor, consider its size, accuracy, viewing angle, color depth, and protection level. Additionally, it is important to focus on different application scenarios and determine its suitability after purchase to ensure that the industrial monitor can meet the needs of applications in different environments.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com