What is a Resistive Touch Screen?

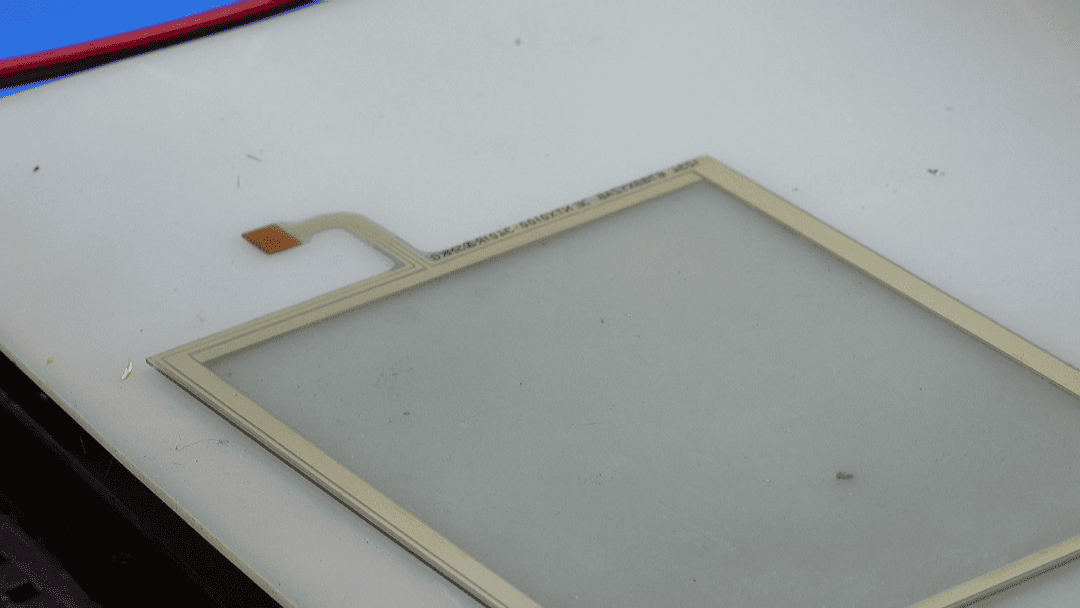

A resistive touch screen is a pressure-sensitive display technology consisting of two transparent conductive layers separated by insulating spacers, with electrodes along the edges. The top layer is typically made of flexible plastic (PET film), while the bottom layer is glass—both coated with indium tin oxide (ITO) as conductive surfaces. When pressed, the top layer bends to make contact with the bottom ITO layer, creating a touchpoint. The controller detects voltage changes via an ADC (analog-to-digital converter) to calculate the X/Y coordinates of the touch. Resistive screens use 4-, 5-, 7-, or 8-wire configurations to generate bias voltage for accurate touch detection.

Resistive Touch Screen Advantages:

-

High Precision: Can detect touches at single-pixel accuracy.

-

Environmental Resilience: Works reliably in dusty, wet, or extreme-temperature conditions.

-

Durability: Responds to any input (fingers, stylus, gloved hands, etc.).

-

Cost-Effective: Mature technology with low production costs.

Resistive Touch Screen Disadvantages:

-

No True Multi-Touch: Only supports single-point input; multiple touches cause errors.

-

Wear & Tear: Requires protective films and periodic calibration. Vulnerable to scratches.

-

Temperature/Humidity Sensitivity: Performance may degrade in harsh environments.

Due to its simplicity and affordability, resistive touch screens are widely used in ATMs, kiosks, and industrial controls. However, they’re rarely found in smartphones or devices requiring multi-touch and high responsiveness, where capacitive screens dominate.

Resistive Touch Screen Connection Process

Resistive touch screen is often used in the industrial control machine industry, like industrial panel pc, android pc, industrialist monitorial and other products, will use resistive touch screen, of course, there are capacitive touch screen.

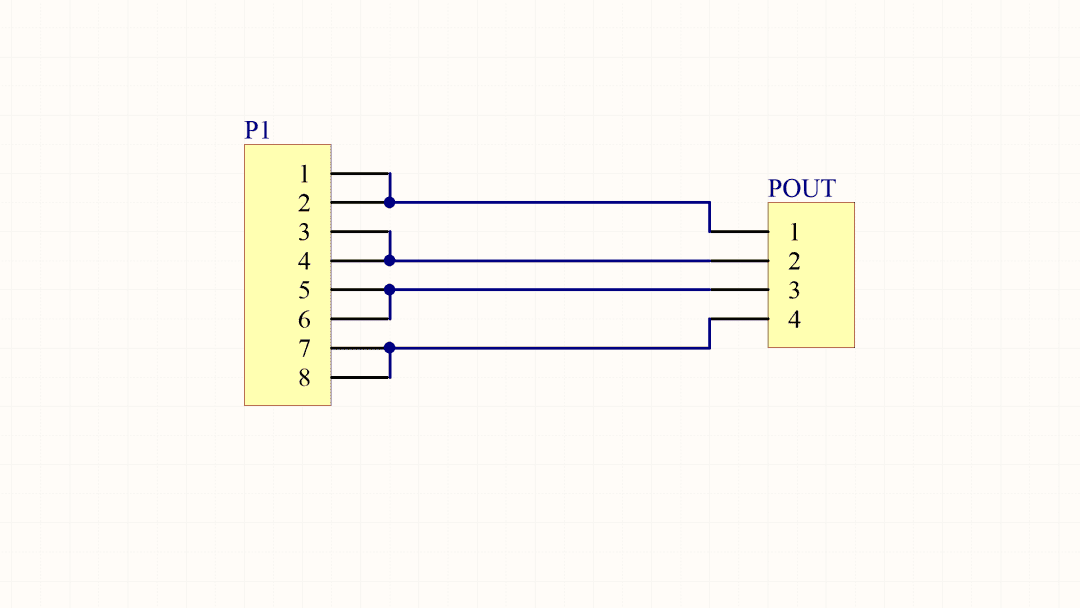

Today COMPT small editor will talk to you about the linking process of resistive touch screen . A resistive touch screen, there are four terminals. Through the soft PCB board, connected to the four sides of the glass plate, through the four sides of the resistance formed by the voltage divider, you can get the surface of the corresponding position of the touch point.

1. Measurement results

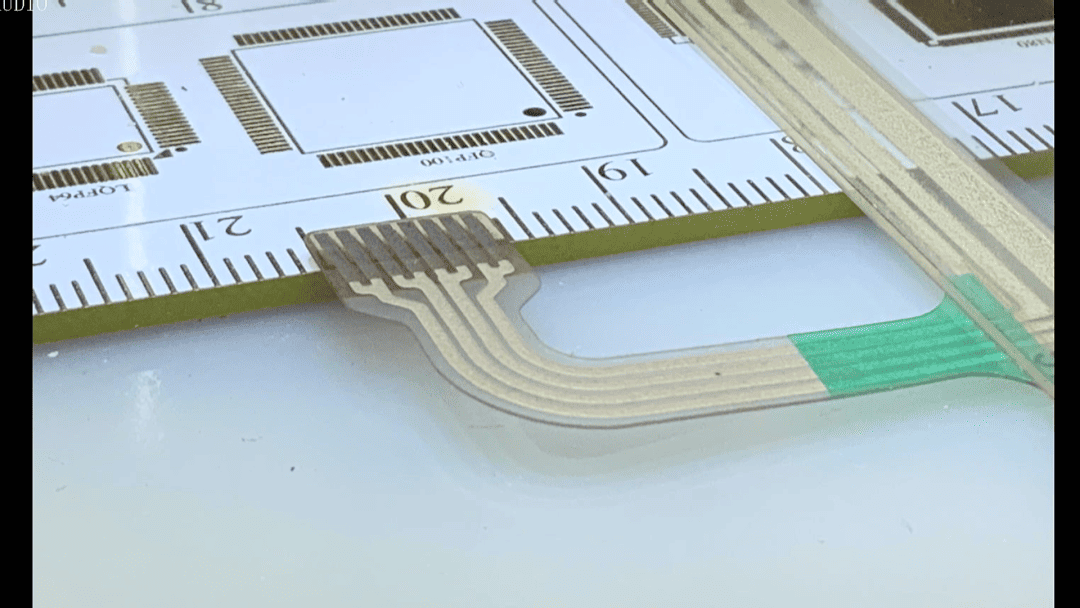

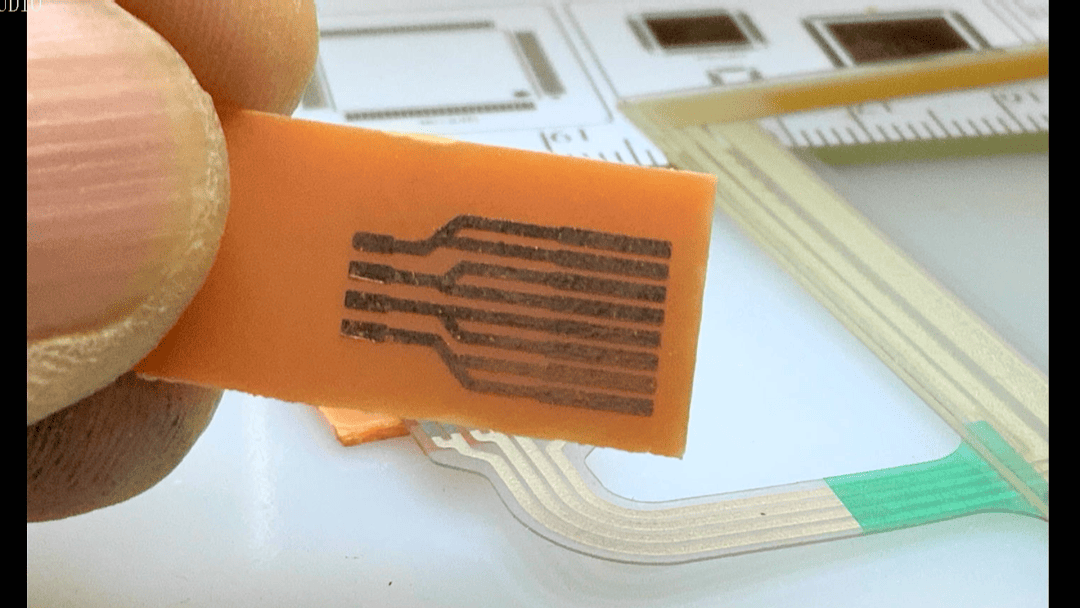

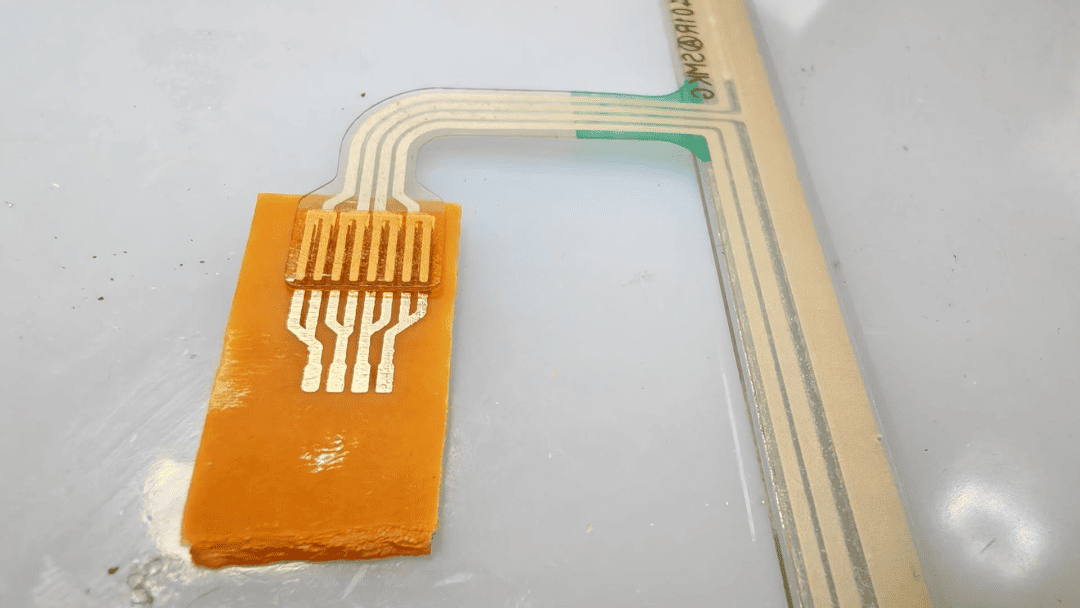

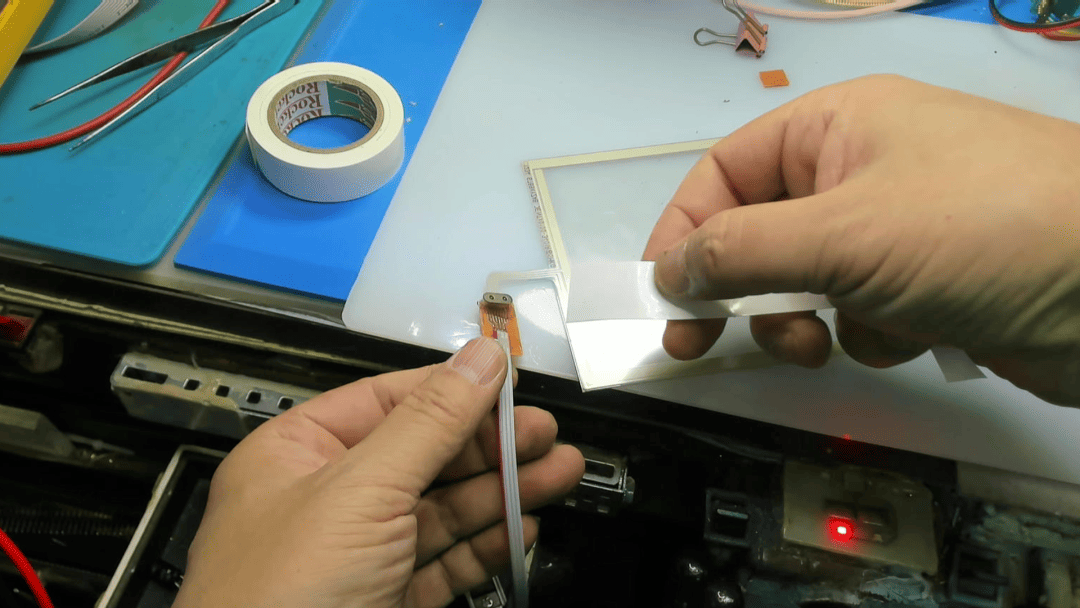

First of all, one of the biggest problems encountered is how to connect the interface of the touch screen. Since it is a carbon film pin, it was originally crimped onto the circuit board, but now we need to make a crimp adapter board to connect the pins of the interface. The following design of the connection of the adapter board, the use of one-minute board method, the production of four adapter boards, and then use the glue to achieve the crimp.

2. Connection test

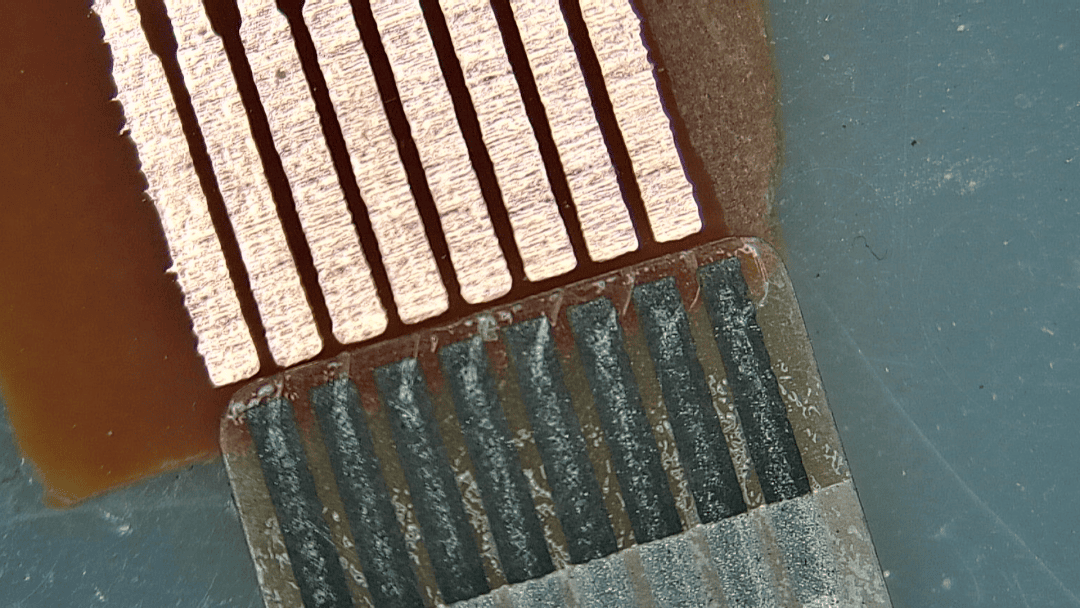

The adapters are aligned with the connector and then crimped together. For fixing, this fast UV curing adhesive is used. However, without pressure, the connector is not effectively connected to the interface.

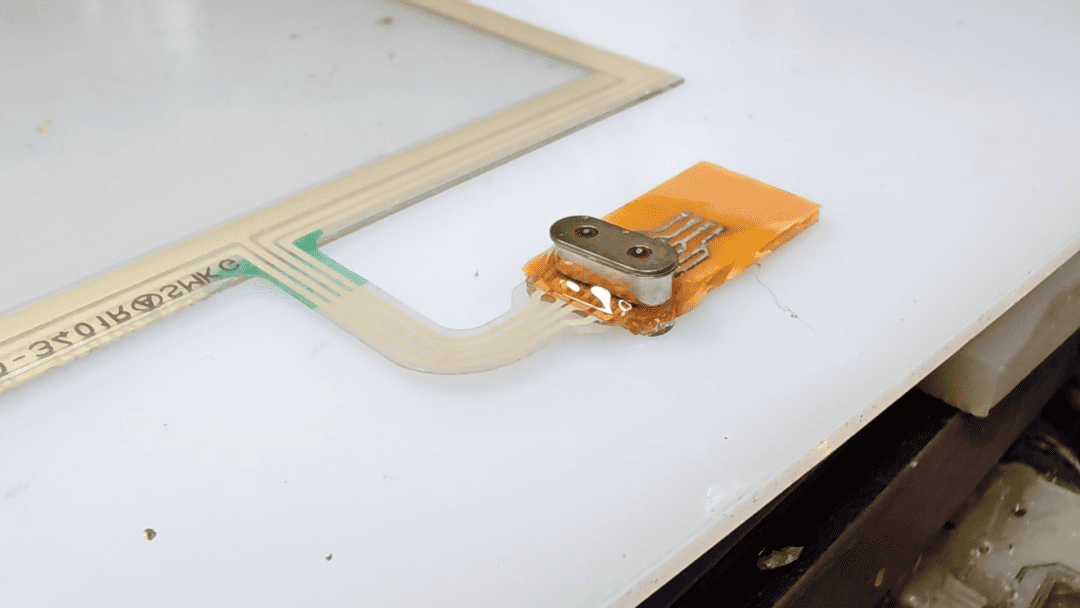

The connector is pressed together with a crystal and cured externally with the UV curing adhesive. This maintains a pressure on the connector.

Measurements showed that one of the pairs of connectors was securely connected, but the other pair of connectors was not making good contact. A white adhesive tape was used to bind the connectors, but one pair was still not securely connected. Finally, we use heat shrink tubing to compress the other pairs of connectors, and after the heat shrink tubing cools down, the other pairs of connectors remain connected normally.

This paper documents the process of connecting the resistive touch screen interface externally, using an adapter plate, connecting the carbon film interface, using external pressure to ensure that the interface is reliably connected. More information about the resistance touch screen can be collected on our website.

How Resistive Touchscreens Work

A resistive touchscreen operates through the following key steps:

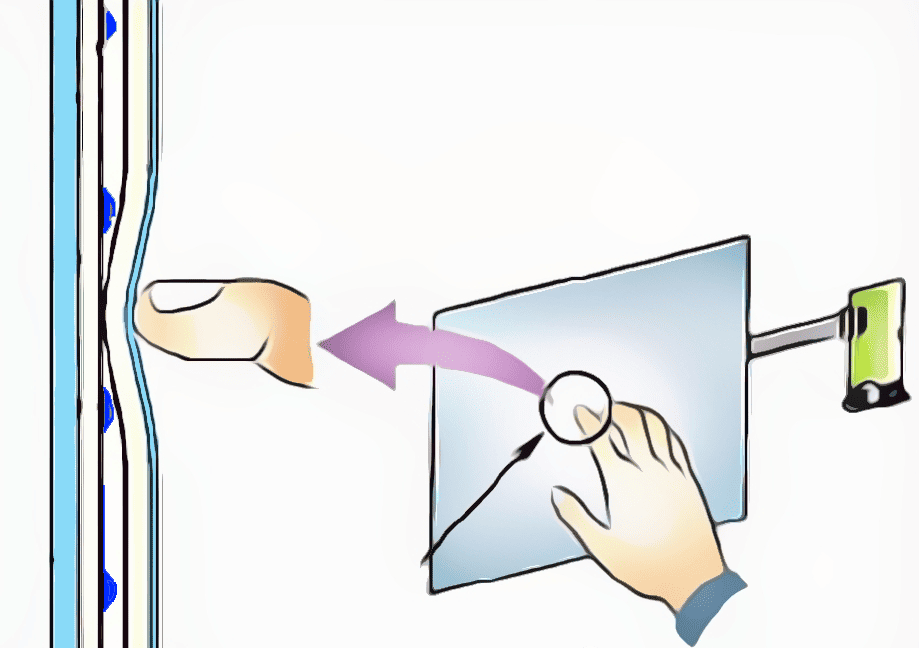

Resistive Touch Screen Pressure Sensing:

When a finger or stylus presses the screen, the flexible top PET film bends downward, causing the upper and lower ITO (Indium Tin Oxide) conductive layers to make contact at the touch point.

Resistive Touch Screen Voltage Measurement:

The voltage at the contact point is proportional to the resistance of the bottom layer. By measuring this voltage, the controller calculates the precise X and Y coordinates of the touch.

Resistive Touch Screen Signal Transmission:

Resistive touchscreens typically use 4-wire, 5-wire, 7-wire, or 8-wire configurations to generate a bias voltage across the screen and read back the touchpoint voltage.

Resistive Touch Screen Pressure Detection:

These screens can measure pressure levels—greater force improves contact between the layers, reducing resistance and allowing for pressure-sensitive input.

Resistive Touch Screen Pros & Cons:

Due to their simplicity and low cost, resistive touchscreens are widely used in ATMs, public kiosks, and industrial controls. However, they lack the durability and precision required for modern smartphones, which favor capacitive technology.

How Long Does a Resistive Touch Screen Typically Last?

The lifespan of a resistive touch screen is generally long, but it ultimately depends on usage conditions, frequency of use, and maintenance. Under normal operating conditions, a resistive touch screen can last 5 years or more. Due to their durability and reliability, resistive touch screens are commonly used in industrial and medical equipment, where frequent operation and harsh environments are common.

However, compared to capacitive touch screens, resistive touch screens may have slower response times and lower display clarity.

About Resistive Touch Screen FAQ

-

What is a resistive touch screen and how does it work?

- A resistive touch screen is made of two flexible layers separated by a gap. When pressure is applied, the layers make contact, allowing the system to determine the touch point based on voltage changes.

-

How do I connect a 4-wire resistive touch screen to a controller?

- To connect a 4-wire resistive screen, match the screen’s X+ X- and Y+ Y- lines to the corresponding input pins on the touch controller. Be sure to reference the manufacturer’s wiring diagram.

-

What’s the difference between 4-wire and 5-wire resistive touch screens?

- A 4-wire touch screen uses two electrodes per axis, while a 5-wire screen uses four electrodes on the bottom layer and one sensing wire on the top. 5-wire models are generally more durable and accurate over time.

-

Do resistive touch screens need calibration after connection?

- Yes, most resistive touch screens require software-based calibration after connection to ensure touch accuracy, especially if used with custom controllers or displays.

-

Can resistive touch screens work in outdoor or industrial environments?

- Yes, resistive touch screens are highly resistant to dust, moisture, and temperature changes, making them ideal for industrial, medical, and outdoor applications.

-

What interface is typically used to connect resistive touch screens to a PC?

- Common interfaces include USB or RS232, depending on the touch controller used. Some industrial panel PCs have built-in touch screen controller support.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com