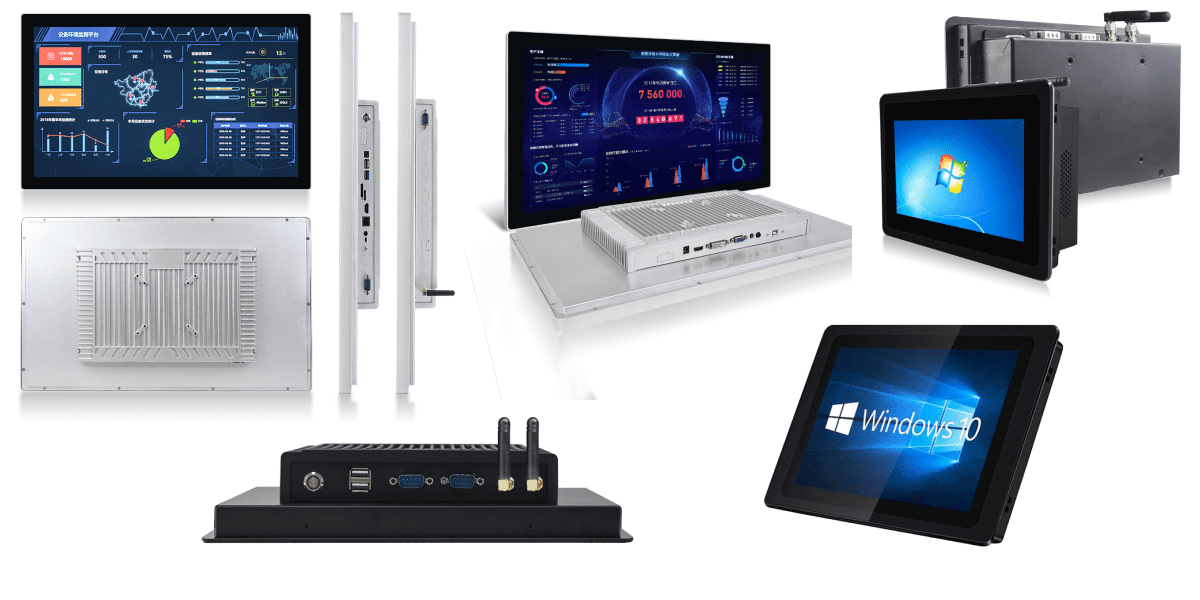

I’m Penny, we at COMPT are a China-based industrial PC manufacturer with 10 years of experience in custom development and production. We provide customised solutions and cost-effective industrial Panel PCs, industrial monitors, mini PCs and rugged tablet PCs for global customers in a wide range of applications such as industrial control sites, automated smart manufacturing, smart agriculture, smart cities, smart transportation and other fields. Our markets include 50% of the EU market, 30% of the US market and 20% of the Chinese market.

1. Basic concept of industrial display

An industrial display is a display device designed for harsh environments, able to withstand harsh conditions such as high temperature, low temperature, vibration, dust and moisture. Unlike consumer-grade displays, industrial monitor have more rugged components and structures that are suitable for long-term continuous use.

Differences between industrial and consumer monitor

Durability and Reliability: Industrial monitors are designed for use in harsh environments and are able to withstand vibration, shock, and temperature extremes, whereas consumer-grade monitors are typically only suitable for home or office environments.

Quality and Lifespan: Industrial monitor are made with high-quality, industrial-grade components and have a lifespan of 7-10 years, while consumer-grade displays typically have a lifespan of 3-5 years.

Application Scenarios: Industrial monitor are widely used in manufacturing, military, medical, and marine applications, while consumer-grade displays are mainly used in homes and offices.

For more detailed differences click: Consumer VS Industrial

2. Types of industrial display designs

According to different installation needs and environmental requirements, there are various design types of industrial monitors:

Embedded Open Frame Industrial monitors: Embedded into an existing front panel from the rear, customer-specific fixing points and front panels can be readily implemented.

Embedded Panel Mount Industrial monitors: mounted from the front in a mounting wall cut-out with screw connections made from the rear.

Recessed 19″ rack mount industrial monitors: prepared for mounting in a 19″ rack, the display is fixed to the rack using an adapter plate.

VESA Mount Industrial monitors: Features VESA mounting interface for flush, articulating or rack mounting.

Stainless Steel Industrial monitors: Full stainless steel enclosure, easy to clean, corrosion resistant, with full IP65 protection, including interface sections.

Fully Protected Industrial monitors: with a robust aluminium casing and a protective film keypad that is resistant to abrasion, scratches and chemicals.

3. Application areas of industrial monitors

- Food, chemical and pharmaceutical industries

- Medical technology and process engineering

- Plant engineering and mechanical engineering

- Automation

- Intelligent agriculture

- Intelligent transport

- Intelligent Healthcare

- Internet of Everything

- Intelligent Vehicle

4. Key characteristics of industrial monitors

Reliability and durability

Industrial monitors must be able to maintain stable operation in extreme environments, be resistant to vibration, environmental influences and temperature fluctuations, and be suitable for 24-hour continuous operation.

Screen Characteristics

Industrial monitors are available in display sizes ranging from 7.0 to 23.8 inches with resolutions ranging from 800×480 to 1920×1080. The displays have high contrast and light resistance and are capable of operating in harsh environments.

Operating Options

Depending on the application requirements, different touch technologies can be selected

based on the surface acoustic wave principle, activated by finger touch.

Resistive Touch Screen: Operated by pressure gestures, has a two-layer structure and can be operated with gloves or using a pen.

Projected Capacitive Multi-Touch Panel (PCAP): Supports multi-touch, is resistant to dirt and liquids, is easy to clean, and has a high degree of transparency and a clear field of view.

Cleaning and Maintenance

Industrial monitors have good resistance to vibration, environmental influences and temperature fluctuations. ip protection ratings define how well a device is protected against foreign objects and water, e.g. ip65 means it is dustproof and protects against sprays of water at any angle. the smooth, seamless surface of PCAP touchscreens also aids in cleaning.

5. Advantages of industrial monitors

Efficient touch control: Industrial touch monitors provide a more efficient operating experience than traditional monitors.

Space-saving design: Industrial monitors are often compactly designed to fit into a variety of installation environments, saving space.

Multiple Configurations and Customisation Options: Industrial monitors can be customised to provide a variety of configurations according to different application requirements.

High-quality components and long lifespan: industrial monitors use high-quality components with a long lifespan, reducing the frequency of replacement and maintenance.

6.Classification and Differences of Industrial Monitors

To accommodate various application scenarios, industrial displays can be categorized in the following ways:

6.1.By Usage Environment

Indoor Industrial Monitors: Suitable for stable environments like factory floors and data centers, emphasizing durability and long-term operation.

Outdoor Industrial Displays: Feature high brightness, waterproofing, dust resistance, and tolerance to extreme temperatures, enabling stable performance in harsh conditions such as strong light, rain, or snow.

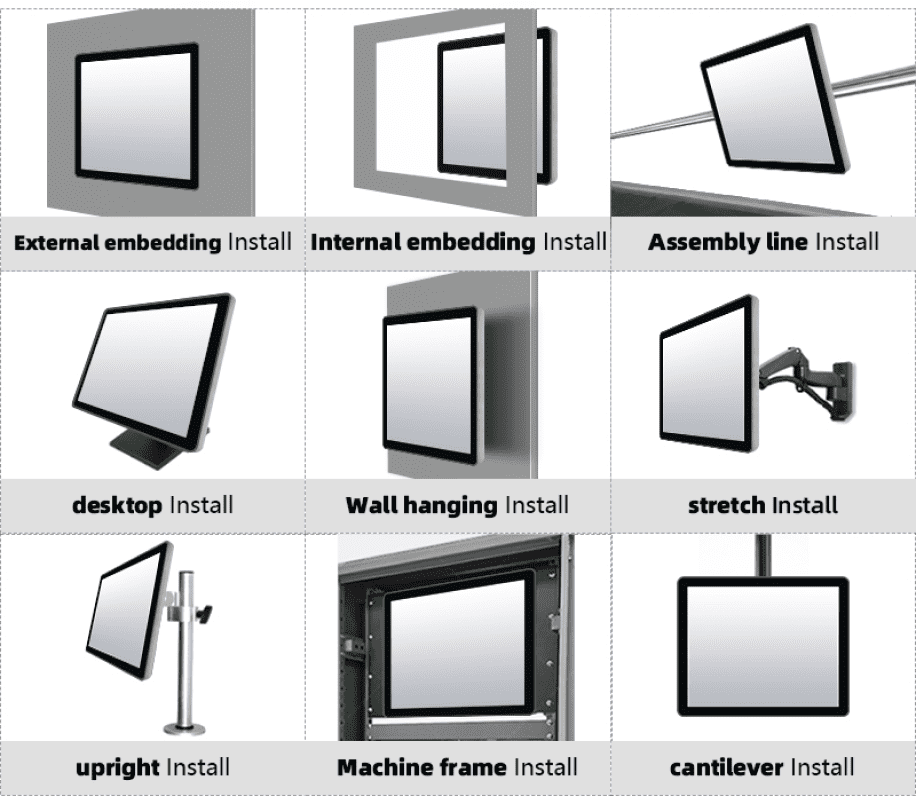

6.2.By Mounting Method

Wall-Mount Industrial Displays: Installed on walls via VESA holes, saving space. Commonly used in monitoring and control centers.

Embedded Industrial Monitors: Integrated into cabinets or equipment with a flush front panel, widely used in self-service terminals, medical devices, etc.

Open-Frame Monitors: Lack an enclosure, making them ideal for secondary development and custom embedded projects.

6.3.By Protection Rating

IP65 and Higher Displays: Offer dustproof and water-jet resistance, suitable for humid or dusty environments.

Explosion-Proof Monitors: Designed for high-risk industries like oil and gas, preventing explosions caused by display malfunctions.

6.4.By Touch Functionality

Touchscreen Industrial Monitors: Support capacitive or resistive touch, ideal for scenarios requiring human-machine interaction.

Non-Touch Industrial Displays: Solely for data or monitoring display, without direct user touch input.

6.5.By Interface Type

HDMI/DP/VGA Industrial Monitors: Compatible with various industrial control hosts, supporting multiple signal inputs.

Monitors with Serial Ports (RS232/RS485) or USB Touch Interfaces: Adapt to legacy or specialized control systems.

7. Market and purchase recommendations for industrial monitors

Ideal price/performance ratio

Long-term market availability

Industrial monitors play an important role in industrial environments, and their high reliability and durability make them ideal for a variety of demanding applications. Choosing the right industrial monitor for your specific needs can effectively improve productivity and ease of operation. We at COMPT offer full-size PCs and monitors from 7” to 23.8” with a variety of customised interfaces to suit all customer application scenarios. If you have any needs or questions, our professional team will provide you with the most suitable solution.

8.FAQ

8.1. What is an industrial monitor?

An industrial monitor is a display device designed for harsh environments, featuring dustproof, waterproof, wide temperature resistance, and vibration resistance. It is widely used in industrial automation, smart manufacturing, transportation, and medical equipment.

8.2. What are the differences between an industrial monitor and a regular monitor?

An industrial monitor uses industrial-grade components, supports continuous 24/7 operation, and offers greater reliability and durability. In contrast, regular monitors are designed for home or office use with limited lifespan and protection.

8.3. Can an industrial monitor be used outdoors?

Yes. For outdoor applications, industrial monitors are typically equipped with high-brightness screens (up to 1000 nits) and IP65-rated protection, ensuring clear visibility under direct sunlight and stable operation in rain or extreme temperatures.

8.4. What should I consider when choosing an industrial monitor?

Key factors include protection rating (e.g., IP65 or IP67), operating temperature range, brightness, input interfaces (HDMI, VGA, USB), touch functionality (capacitive or resistive), size, and installation method (wall-mounted or panel-mounted).

8.5. Is it possible to customize an industrial monitor?

Yes. Industrial monitors can be customized based on project requirements, including interface layout, size, brightness level, touch technology, and protection grade to meet specific application needs.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com