Key Takeaways for industrial touch screen monitor

-

Pick a strong monitor that is made well. Put it in a clean and dry spot. Keep it away from sunlight and big machines. This helps stop damage and keeps it from getting too hot.

-

Attach your monitor tightly with the right tools. This keeps it steady and easy to see. It helps you work better and stay safe.

-

Use the right way to touch the screen. Be gentle so you do not break it. Keep the monitor clean and check the cables often. This helps stop common problems.

-

Clean your monitor often with a soft cloth and mild cleaner. Check it often to find small problems early. This can help you avoid big repairs.

-

Use the right IP or NEMA-rated enclosure to protect your monitor. This keeps out dust, water, and bad weather. Update the software to keep it working well.

Industrial Monitor Installation

Environment Choice

Pick a good spot for your industrial touch screen monitor. Check if the room is too hot or too cold. If it gets too hot, the monitor can overheat and not work right. If it is too cold, the screen might be slow or not respond. Dust and water can get inside and cause trouble. Try to put the monitor in a place that is dry and clean. If your factory has lots of dust or water, use a protective enclosure. This keeps dirt and spills away from the monitor. Some monitors work in very hot or cold places, from -20°C to +60°C. These monitors have strong cases made of aluminum or stainless steel. High-brightness screens are easy to see, even when it is very bright.

Tip: Keep your monitor out of direct sunlight and away from big machines. This helps stop glare and shaking.

Mounting Options

There are different ways to mount your industrial touch screen monitor. Each way helps keep the monitor safe and steady. Here are some ways you can do it:

-

Panel Mount: Put the monitor into a hole in a control panel. The screen stays flat with the surface and the edges are safe.

-

Rack Mount: Place the monitor in a rack with other tools. This saves space and keeps things neat.

-

Wall Mount: Hang the monitor on a wall. This is good if you need more counter space.

-

Open Frame: Use this if you want to build the monitor into special equipment.

Always use the right parts to mount your monitor. A secure setup stops the monitor from shaking or falling. In one factory, workers put a high-brightness monitor above machines. It was easy to see alarms and machine status. The team could act faster and make more products. Another plant put monitors on important pumps and reactors. This helped them control things better and waste less.

Note: Connect your monitor to power and data lines with care. Make sure all cables are tight and safe.

Usage Tips for Industrial Touch Screen Monitor

Touch Methods

You can extend the life of your industrial touch screen monitor by using the right touch methods. Different technologies work best in different settings. Here are some ways you can interact with your screen:

-

Resistive touch screens respond to pressure. You can use your finger, a stylus, or even gloves. This is helpful in factories where you need to wear protective gear.

-

Projected capacitive touch screens use a thick glass layer. These screens let you use more than one finger at a time. They also give you precise control and last longer because the glass protects the screen.

-

Some screens have special coatings and sealed designs. These features keep out dust, water, and extreme temperatures. Your monitor stays safe and works well in tough places.

-

Haptic feedback gives you a small vibration when you touch the screen. This helps you know your touch worked, even in noisy or dark areas.

Tip: Always use a soft touch. Pressing too hard can damage the screen over time.

Avoiding Damage

You can prevent many common problems by following a few simple steps. These habits help your monitor last longer and work better.

-

Keep your monitor clean. Wipe the screen and vents often to stop dust from building up.

-

Make sure your monitor has good airflow. This prevents overheating, which can cause the screen to fail.

-

Check cables and connections regularly. Loose wires can cause the screen to flicker or stop working.

-

Change the images on your screen often. Leaving the same picture for too long can cause burn-in, which leaves a ghost image that will not go away.

-

Lower the brightness when you can. Bright screens wear out faster.

-

Use a surge protector. This keeps your monitor safe from sudden power spikes.

-

Avoid turning your monitor on and off too often. This helps the inside parts last longer.

-

Protect your monitor from rain, dust, and strong sunlight. Use covers or enclosures if needed.

Note: Watch for signs like flickering, dead spots, or color changes. Fixing small problems early can stop bigger issues later.

Cleaning & Maintenance

Cleaning Steps

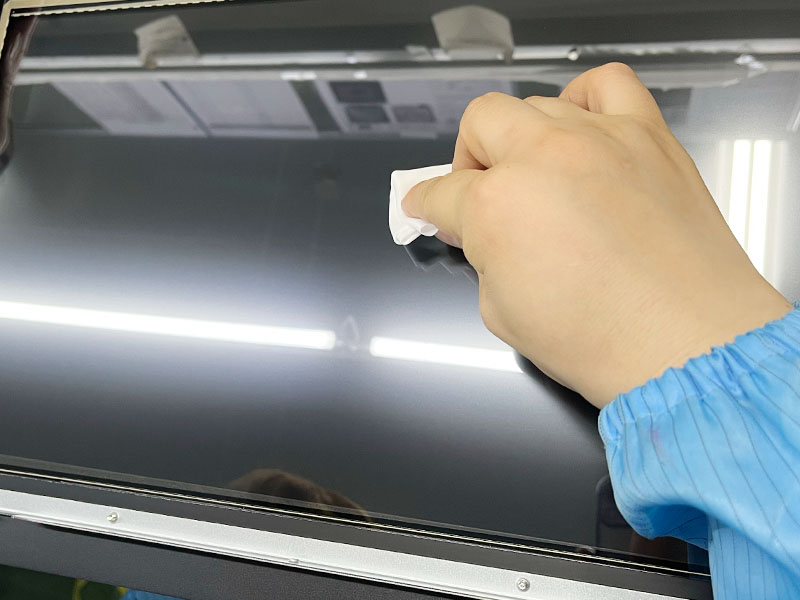

Keeping your industrial touch screen monitor clean helps it work better and last longer. You should follow safe cleaning steps to protect the screen and its parts. Here is a simple guide you can use:

-

Power off your monitor and unplug it before you start cleaning. This keeps you safe and protects the device.

-

Use a soft, lint-free or microfiber cloth. Avoid paper towels or rough sponges because they can scratch the screen.

-

Dampen the cloth with a small amount of water or a mild cleaning solution. You can use a mix of distilled water and a drop of mild dish soap. Do not use harsh chemicals, ammonia, or strong solvents.

-

Never spray liquid directly onto the screen. Always put the cleaner on the cloth first.

-

Wipe the screen gently in small circles. Use light pressure to avoid damaging the surface.

-

For tough spots, use a special LCD cleaning solution or a cloth with a bit more soap. Do not scrub hard.

-

Dry the screen with a clean, dry microfiber cloth. Make sure no moisture stays on the edges.

-

Clean the frame and buttons with the same gentle method.

-

Dust the screen often to stop dirt from building up.

-

If you use a screen protector, check it for scratches and replace it if needed.

Tip: Clean your monitor in a well-lit area. This helps you see smudges and dirt better.

You should also disinfect the screen if many people use it. Use wipes with at least 70% alcohol, but make sure they are safe for screens. Always check your device manual for special cleaning rules.

Regular Checks

Regular checks help you find problems early and keep your monitor working well. Many factories lose money when machines stop because of small issues that could have been fixed early. Studies show that companies with regular maintenance have up to 44% less downtime.

Here are some things you should check:

-

Look for cracks, scratches, or chips on the screen. Small marks can grow and cause bigger problems.

-

Check all cables and connections. Make sure they are tight and not worn out.

-

Inspect the frame and mounting. The monitor should not shake or move.

-

Test the touch function. Make sure the screen responds everywhere.

-

Watch for flickering, dead spots, or color changes. These signs mean you should fix the monitor soon.

-

Clean vents and fans to stop dust from blocking airflow.

-

Calibrate the screen if you notice touch errors.

-

Review the cleaning and maintenance log. Make sure you follow a regular schedule.

Note: Proactive care helps you avoid costly repairs and keeps your industrial touch screen monitor running smoothly.

A good cleaning and maintenance plan can save you time and money. You will have fewer breakdowns and your monitor will last longer.

Protection

IP Ratings

You need to know how well your monitor stands up to dust and water. IP ratings tell you this. IP stands for “Ingress Protection.” The first number shows how well the monitor keeps out dust. The second number shows how well it keeps out water.

-

IP65: This rating means your monitor is dust-tight. It also resists water jets from any direction. You can use it in places where you clean with a hose or where dust is common.

-

IP66: This rating gives you even more protection. Your monitor can handle strong water jets and heavy dust. You can use it in washdown areas or outside.

-

NEMA 4X: This is a North American standard. It means your monitor is safe from dust, rain, splashing water, and even corrosion. You often see this rating in food plants or chemical factories.

Tip: Always check the IP or NEMA rating before you install your industrial touch screen monitor. The right rating keeps your monitor safe and working longer.

Enclosures & Covers

You can make your monitor last longer by using enclosures and covers. These add a strong layer of protection. They keep out dust, water, and even strong cleaners. Many factories use enclosures to protect monitors in tough places.

-

Premio’s monitors work in dairy plants, AI vision inspection, and thermography labs. These places have dust, water, and cleaning chemicals. The monitors use IP66 or IP69K enclosures. This keeps them safe and working well.

-

Some companies upgrade to rugged enclosures with tough glass and special seals. These enclosures block dirt, grease, and vibration. They also help the screen stay clear in bright sunlight.

-

Enclosures make it easy to fix or upgrade your monitor. You can open them fast for repairs. This means less downtime and more work done.

-

A steel body and tough glass protect your monitor from bumps and theft. Secure locks keep your monitor safe from tampering.

Here is a table that shows how enclosure features help you:

|

Feature |

Benefit |

|---|---|

|

Powder coated mild steel |

Stops dust, dirt, and bumps in harsh places |

|

NEMA 4 sealing |

Keeps out water and dust in factories |

|

Water-repellent seals |

Protects from damage during washdowns |

|

Surge-protected power |

Guards against sudden power spikes |

|

Many mounting options |

Lets you put the monitor where you need it |

|

Secure stainless steel locks |

Stops theft and keeps the monitor sealed |

Note: Using the right enclosure or cover helps your industrial touch screen monitor last longer. You get better uptime and lower repair costs.

You should always match the enclosure to your work area. In wet or dusty places, pick a high IP or NEMA rating. In places with lots of cleaning, use water-repellent seals. This way, your monitor stays safe and works well for years.

Software & Support

Updates

You should keep your industrial touch screen monitor’s software up to date. Updates help your monitor run better and stay safe from bugs or hackers. Many companies release new software to fix problems or add features. You can check for updates in a few easy steps:

-

Visit the manufacturer’s website. Look for the support or downloads section.

-

Find your monitor’s model number. You can see it on the back or in the settings menu.

-

Download the latest firmware or driver updates. Make sure you pick the right files for your model.

-

Follow the update instructions. Some updates need a USB drive. Others use a network connection.

-

Restart your monitor after the update. This helps the new software work right.

Tip: Set a reminder to check for updates every few months. This keeps your monitor working at its best.

You should also update any apps or programs you use with your monitor. Old software can cause crashes or slowdowns.

Troubleshooting

Sometimes, your monitor may not work as expected. You can fix many problems yourself by following simple steps. Here is a quick troubleshooting guide:

-

Screen does not turn on: Check the power cable and outlet. Try a different power source.

-

Touch does not respond: Clean the screen. Make sure you use the right touch method for your monitor type.

-

Image looks strange: Adjust the brightness or contrast. Check the video cable for damage.

-

Monitor freezes: Restart the monitor. If it still freezes, update the software.

-

Error messages: Write down the message. Look it up in the user manual or on the manufacturer’s website.

Note: If you cannot fix the problem, contact technical support. Give them your monitor’s model number and a clear description of the issue.

You can solve most issues with regular updates and simple checks. This helps your monitor last longer and work better every day.

You can help your industrial touch screen monitor last longer. Clean the monitor often and look for any damage. Use the monitor the right way every day. Taking care of it and checking it often helps you save money. This also keeps your equipment working well. The table below shows how these steps help you. You will have less downtime, spend less money, and stay safer.

|

Benefit |

Result |

|---|---|

|

Downtime Reduction |

|

|

Life Extension |

20-40% longer lifespan |

|

Cost Reduction |

47% lower costs |

If you take care of your monitor, it works better and has fewer problems. You get more use from it and worry less.

FAQ

How often should you clean your industrial touch screen monitor?

You should clean your monitor at least once a week. If your area has a lot of dust or dirt, clean it more often. Use a soft, damp cloth for best results.

What should you avoid when cleaning the screen?

Never use harsh chemicals, ammonia, or rough sponges. These can scratch or damage the screen. Always use a microfiber cloth and a gentle cleaner.

Can you use gloves with all touch screen monitors?

You can use gloves with resistive touch screens. For capacitive screens, use gloves made for touch screens. Regular gloves may not work well.

What should you do if the monitor stops responding to touch?

-

Check all cables and power connections.

-

Clean the screen gently.

-

Restart the monitor.

-

If it still does not work, contact technical support.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com