The industrial sector has been ever changing involving difficult environments and situations. Aside from construction, and warehousing, the industrial sector involves factory work. Heat, moisture, and industrial vibrations are all present throughout every level of work. Everyday environments like these help explain why off-the-shelf PCs are not built to survive the harsh and rough industrial work environment. This is the main reason fully integrated industrial panel pcs are so important. The modern industrial worker depends on them.

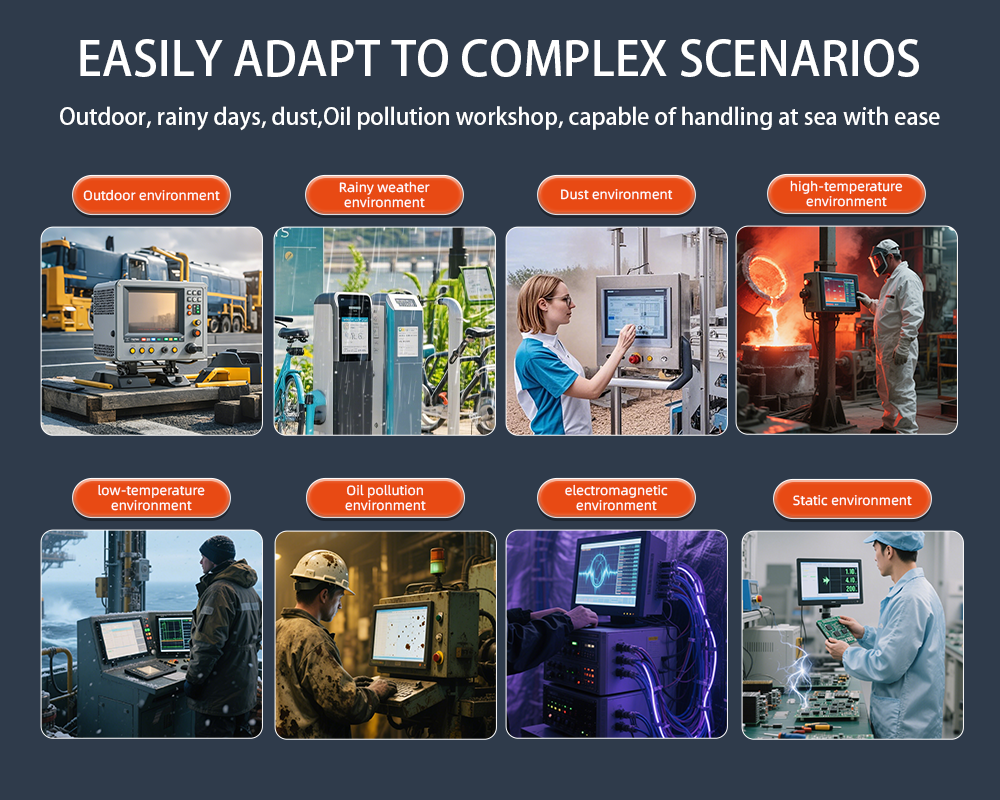

A panel PC is an integrated touchscreen and computer combo. Rugged panel PC units are built to operate fully for long continuous shifts, even extreme work environments. Extreme environments are an example of seamless integration. Panel PC units are adopted widely throughout food processing, logistics, automotive, gas and oil, and manufacturing.

Remote working has now become a common practice, so PC panel units offer a unique position for replacing fully integrated human worker stations. Panel PC units transform and become the main point of operator to machine communication. This is why, at the remote enterprise divisions industrial partition panel PCs, we focus on industrial ruggedness, longevity, and stability. This article is going to focus on giving a detailed evaluation and overview of the industrial panel PC features, applications, criteria for selection, and maintenance for your needs.

Core Features of Industrial-Grade Panel PCs

An industrial-grade panel PC is a custom designed computer solution where every feature is designed to minimize failure and optimize reliability over long periods of time.

1. Durable Construction

Industrial-grade panel PCs are built with a rugged and durable construction. Industrial environments can be messy with dust and liquids as well as high amounts of vibration. Industrial-grade panel PCs use strong metal housings and sealed front panels to withstand the environment.

2. IP Grade Standards

IP rating standards are a great way of determining how well a device is protected. If a panel PC has an IP rating of IP65, that means it is dust tight and protected from water jets. While this is a common rating for a panel PC, it is the minimum for use in food and beverage processing and outdoor environments.

3. Resistance to Mechanical Shock

Industrial environments can also be rough mechanically with impacts and high amounts of vibration. Industrial panel PCs are rigorously tested to withstand mechanical shocks and constant industrial vibration. This is to ensure that the PCs continue to operate reliably over long periods of time.

4. Fanless Cooling Technology: Ensuring 24/7 Reliability in Industrial Panel PCs

Fanless cooling technology sets industrial panel PCs apart from typical consumer systems. These industrial PCs use passive cooling, utilizing heat sinks and metal enclosures, rather than fans.

Fanless design provides a higher level of reliability than traditional consumer PCs. Fans can collect dust and wear out over time, resulting in overheating that causes systems to shut down. This is particularly problematic in industrial settings where downtime is costly. Fanless systems eliminate this risk.

In addition, fanless computers operate at lower noise levels and don’t need to be serviced as frequently. This makes them especially useful in systems that are exposed to heavy dust, oil mist, or airborne particulates. This design allows industrial panel PCs to fully operate 24/7.

5. High Brightness Displays: Optimal Visibility for Outdoor & High-Glare Industrial Settings

Reading data is an essential part of every industrial job. To minimize the risk of data entry and other mistakes, strong visibility is needed across the PC screen. Industrial panel PCs commonly result from collaborative efforts and present opportunities for integration of high brightness displays that remain readable in both bright sunlight and in high indoor lighting.

These displyas are often used in outdoor cabinets and production areas with reflective surfaces. Visibility is improved with anti-glare coatings. Touchscreens are designed to work accurateley evwn when operators are gloved or have wet hands.

Enhanced display performance increases efficiency and safety, further enhancing user comfort especially during extended shifts.

6. Extreme Operating Conditions: -20°C to 60°C

Industrial panel PCs are designed for extreme temperature environments. Range support for many models is in the range of -20°C to 60°C. These are applicable in environments such as cold storage, outdoor settings, and hot production settings.

Unlike Consumer PCs which are designed for the office, Industrial panel PCs are outfitted with special components that are temperature agnostic. To avoid error, these components ensure steady performance with no unexpected shutdowns.

This is especially relevant for industries, such as cold storage, that do not have authority over their environment.

7. Modular I/O Interfaces: Customizable Connectivity for Diverse Industrial Settings

Specific connections are often required when using industrial systems. As such, the I/O modular interfaces of the industrial panel PCs include: USB, Ethernet, RS232/485, CAN bus, and GPIO.

With I/O modular design, users are able to customize their panel PCs to meet their application requirements. This design is applicable for machine control, data collection, and automation and monitoring.

Here at gdcompt.com, we appreciate that every industrial project is unique. Flexible I/O means that the panel PC integrates into existing systems without any expensive revisions.

Panel PCs can be utilized in a variety of different industries.

Industrial panel PCs are used across many industries because they adapt easily to different environments and tasks.

Panel PCs in Smart Manufacturing: Supporting Factory Automation 4.0

In smart manufacturing, the central control units are panel PCs. They provide operators with updates, alerts, and summaries on the status of machines and production. Operators then make necessary adjustments to processes to optimize production, resulting in time and error reduction.

By integrating machines with software and sensors, they advance the goals of Industry 4.0. Panel PCs continue to be a vital resource in fully automated factories, as they create and analyze data to help optimize factory workflows and analysis to assess future maintenance.

Panel PCs in Warehouse & Logistics: Streamlining Inventory & Material Handling

Speed and precision are critical to success in a warehouse environment. Panel PCs are essential in systems for material handling, and help streamline order fulfillment and control inventory.

Industrial panel PCs are designed to withstand dust and shocks and can be deployed in wall, workstation, or vehicle mounts. For rapidly changing environments, immediate access to up to date information enhances productivity and minimizes errors, particularly for high-speed teams.

Panel PCs for Food and Beverage sector: Enclosed Housings and Carpenter Certifications

The food and beverage sector is the most demanding in terms of the level of professionalism exhibited by industrial panel pc suppliers. Enclosed industrial panel PCs are the norm. When we say enclose, we really mean enclose. When we say rough, we mean really rough.

The odd combination of “rough closed construction” and “cleaning construction” gives a hint of the Carpenter certifications. These enclosures also have the FDA and CE certifications.

Automotive Manufacturing Panel PCs: Monitoring Real-Time Production Line Data

Most flexible systems that are integrated into new line systems challenges, are most efficient, most removable and most reliable real-time systems – best eliminators of potential line systems challenges. Panel PCs are most flexible in every integration.

Constant and shift support are seen as high dwell and high vibration systems. In dense systems, Panel PCs are often relied on in data systems. In environments of high-volume line production, the use of Panel PCs has become essential for the integration of line systems.

Panel PCs in the Oil and Gas Field: Remote Monitoring in Dangerous Work Conditions.

Extreme environments constrain the oil and gas industry. A wide range of conditions and requirements characterizes the panel PC used in these splits. The Panel PCs that support these activities often include features that render them explosion-proof or compliant with ATEX.

These panel PCs support remote control, monitoring, and data logging even in dangerous and remote locations. The ability of these panel PCs to function reliably in harsh environments contributes to the safety and efficiency of operations.

How to Choose the Right Industrial Panel PC in 2026

In 2026, when looking to buy an industrial panel PC, you should look at future needs in addition to current needs. Industrial systems have great longevity, so they must pick panel PCs that will be reliable, compatible, and able to perform for years to come. Performance, reliability, and the manufacturer’s history should be the main considerations for each industrial panel PC.

Let’s start with the ability to do processing. The CPU must be powerful enough to handle current applications, as well as the anticipated software upgrades in the future. Memory and storage are also important considerations. With the growing number of industrial applications that gather and store data, you should select RAM and solid-state storage for the future to ensure you won’t be limited in performance.

At gdcompt.com, we suggest selecting panel PCs that manufacturers claim to have sustained product availability. Doing so minimizes the expense of system redesigns and confirms the availability of spares, repairs, and replacements for several years.

The 7 Things to Think About When Buying An Industrial PC

The system must perform reliably over the years and in a variety of tough conditions. Below are the considerations to take note of before picking the final system.

1. Reliability and Stability: While running continuously without a break, it can create downtime. Choose a system designed with proven long lasting to keep 24/7 operational systems running for years.

2. Build Quality and Rugged Design: Dust, moisture, and vibration protection. Strong enclosers with sealed front panes protect the PC. Industrial grade Components assure the systems can endure working.

3. Methods of Cooling: Fanless systems improve reliability, shift maintenance to lower from moving parts, and lack of dust from built systems.

4. Protection Ratings and Certifications: The systems of the PC can be challenging. Look for IP ratings and safety certificates recognizing the PC conforms to the required levels.

5. Efficient Use of Power: The systems run every day for 24 hours, and that means the empty workloads of the operations become predictable over years.

6. Ease of Maintenance and Serviceability: A system that is easy to access, repair, and upgrade can save time during maintenance. This is especially true for places with high maintenance time costs.

7. Software Compatibility and Future Support: An industrial PC should be able to run the software you have and be able to run updates to the operating system in the future. If updates to the software are available in the long run, that extends the life of the system and reduces the costs associated with owning the system.

Investing time into considering these factors will help guarantee that the industrial PC you choose will end up giving you long life and reliable performance at a great value for the amount you have spent.

Industrial Panel PC vs. Consumer Touchscreen: Why Ruggedization Matters

Compare the costs of an Industrial Panel PC Touch Screen with the Consumer Touch Screen PC. The Touch Screen Consumer PC may look cheaper. Consumer Touch Screen PCs are built for usage in a clean, climate-controlled environment like an office or home. They can only stand a limited amount of exposure to dust, moisture, or extreme heat. They will also be unreliable in areas with vibration.

In contrast with the Consumer Touch Screen PC, Industrial Panel PCs are built for extreme environments. The materials they are built with are Industrial grade, which ensures that Extreme even rougher environments can be handled without damage.

When Consumer Touch PCs are used in Industrial settings, they often break. They are set to be replaced often with newer versions. Industrial Panel PCs are more expensive, but they require less upkeep, are more durable than a standard Consumer Plastic PC, and use less resources over time, which makes them cheaper in the long run.

Ruggedization must be a standard with every industrial Panel PC Thin. They must be built a certain way to meet the standard. But when that standard is met, they can be relied on for great, and consistent performance.

Support and Maintenance of Industrial Panel PCs

Even the best designs need support systems. Monitoring, regular maintenance, and software updates prolong the systems’ useful lives.

Equally important are long-term support and reliable availability of spare parts. At gdcompt.com, we prioritize stable and long-term support to safeguard the investments of our clients.

Final Thoughts

In today’s industrial environments, industrial panel PCs are likely one of the most crucial computers you can get. They function in ways other computers do not. They can be customized in regards to their connectivity, have no fans, and their durability enables applications to range from smart factories to oilfields. The right panel PC encourages positive growth, reduces downtime, and increases efficiency. At gdcompt.com we guarantee to meet the industrial panel PC needs of the industry.

FAQs

1. What are industrial panel PCs used for?

Automation, control, monitoring, and data visualization.

2. How long can industrial panel PCs last?

Most panel PCs are built for 5-10 years of continuous use.

3. Can industrial panel PCs be used outside?

Yes. Many industrial panel PCs offer high brightness display for outdoor use and can operate in extreme temperatures.

4. Are fanless panel PCs reliable?

Undoubtedly, the absence of fans contributes to an increase in reliability and stability by minimizing potential failure points.

5. Is it possible to find industrial panel PCs on gdcompt.com?

Yes, gdcompt.com offers industrial panel PCs with extended support.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com