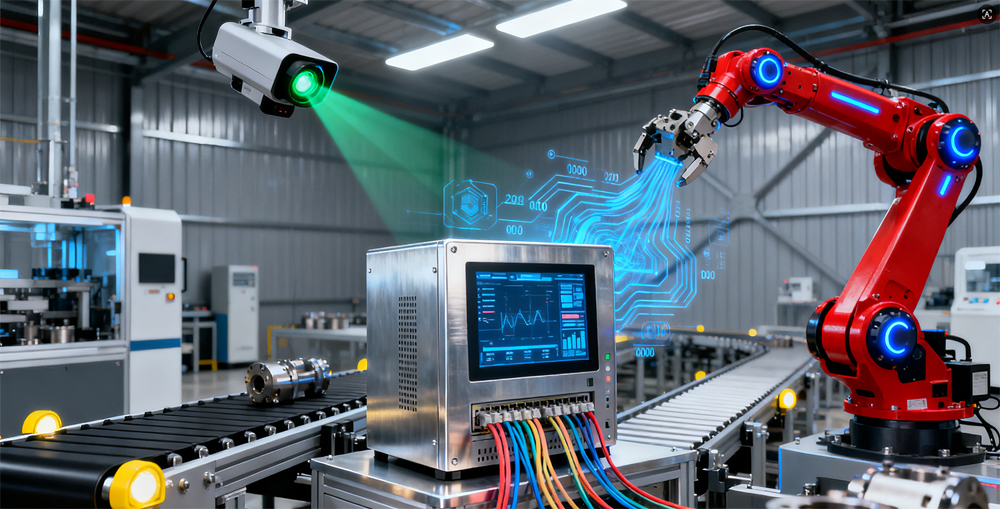

The future of Manufacturing is dependent on Industrial PCs (IPCs) along with Edge AI and the Internet of Things (IoT) technologies. Smart factories powered by these rugged systems fully embrace automation, real-time data processing, and predictive maintenance on the factory floor.

Manufacturing is dependent on IPCs because the rugged computers are the only systems able to work in harsh manufacturing environments. They drive machine vision and are the central control systems for robotics and monitoring systems in automotive, logistics, and food production industries.

The industrial PCs provide near real-time data processing needed for automation in smart factories. They are powered by Edge AI and IoT technologies. With the modern processors like Intel Celeron J1900, Intel J6412 and Alder Lake-N N97, these systems provide the necessary performance, durability, and intelligence of Edge AI at the Edge.

What makes an Industrial PC Different from a Regular PC?

An IPC may look like a desktop or a workstation, but it’s not. These machines are fully designed to work in harsh environments with extreme temperatures and do not alter in form and function with poring dust, moisture, and fluctuating shock and vibration.

Compared to an ordinary office computer, industrial computers have extended fanless cooling, rugged sealed aluminum or stainless steel enclosures, solid state drives, and 24/7 heat and mechanical wear unattended operation. Under the most ordinary conditions, an office computer will have heat coupled with dust. It’ll warp and the plastic enclosures will get compromised. The drives will fail because of vibrations.

Industrial computers also offer different levels of connectivity. They can have RS-232/RS-485 and even Ethernet Pro Power (PoE) interfaces or ports. This allows them to communicate with other industrial equipment. They can communicate with sensors, and programmable logic controllers (PLCs). They form the base of any industrial automation system by forming the interfaces and flowing real time information from the embedded software to the industrial hardware and back.

No minimal dust environment can be guaranteed even outside a food processing point. Computers used in such points, both sealed and screened used to have IP65 and IP67 compliance. The more modern sealed computers even have touchscreen interfaces designed to be used with gloves.

Key Features and Types of Industrial PCs

As one of the additional industrial computing sections, smart factories bring in a variety of different form factors and designs tailored for numerous applications.

Fanless Panel PCs and Embedded Computers

There are many powerful Panel PCs and Fanless Embedded Computers. Most Panel PCs are designed without fans. This self contained unit merges the computer and the display and helps prevent the entrance of dust as well as mechanical breakdown. A Panel PC without a fan equipped with the Intel Celeron J1900 or Intel J6412 processors is able to complete basic machine control, production monitoring, or HMI operations work with users panel.

Additionally, compact embedded computers as automation line console worker computers are used in transportation and digital signage. These low power built embedded computers work flexibly as industrial Linux computers long term reliable can be altered easily. Powerful computing can be used with low maintenance as the systems can be mounted in cabinets or machines directly.

Rugged laptops and tablets

Portable workers and field engineers value these tools the most. These computers and tablets built for these tasks are meant to be used in laptops and tablets. These devices are built to withstand extreme weather, drops, and vibrations as they are built to military standards. With features like built in laptops and rugged notebook PCs are best used for outdoor inspections, logistics, and monitoring oilfields.

The same level of portability can be achieved with the handheld computers and tablets, which are also waterproof. Their touchscreen displays and built in features like GPS and wireless connection makes them a must for conducting remote diagnostics and data collection.

Industrial Monitors and Smart Panels

Industrial monitors and smart panels as visual interface between humans and machines. These monitor smart panels and monitors smart panels designed as touch screen display computers with consideration for outdoor panels for varied climatic and lighting conditions.

Designed with the climate and environment in mind, these smart monitors and panels can function within extreme temperature variations, withstand touch moisture and multi touch controls. These features bring great utility and performance for outdoor kiosks and control rooms. The evolution of smart control panels integrated with artificial intelligence streamlined commands, system and performance visualization, productivity and safety automation and real time maintenance alerts in the industrial sector.

Hardware Powerhouse – Inside the Modern Industrial PC

Beneath the industrial PCs rugged outer casing, the real might of the industrial PCs is in the inner workings and the various powerful elements. Lets see what makes industrial PCs powerful and what makes them future ready.

Intel Celeron J1900/J6412 and Alder Lake-N N97

Intel’s Celeron J1900 and J6412 aligned with Alder Lake-N N97 Modern industrial PCs use advanced Celeron processors that focus on performance and power consumption. The Celeron J1900 and J6412 are common Celeron family members used for embedded and fanless systems designed automation, visualization and control systems as these are quad core power processors.

The Intel Alder Lake-N N97 and 12th/13th Gen Intel Core processors offer powerful AI features and premium graphics. These processors handle multitasking and real-time machine vision image processing, including edge AI analytics and real-time machine vision image processing.

Interfaces: RS-232, RS485, PoE Ethernet

The value of an industrial computer relies on its connectivity options. RS-232, RS485, and PoE Ethernet systems are connected, and is what most industrial systems use, forming the automation and control network backbone.

· RS-485 and RS-232 are older serial communication standards used in connectivity of industrial systems such as sensors, controllers, and actuators. Legacy RS232 systems can be connected to modern computers using USB adapters while RS485 cables can be used as connectors.

· PoE Ethernet (Power over Ethernet) is a telecommunication standard that offers network devices both power and data using a single cable.

All these features provide the industrial computer the flexibility and connectivity needed to work in older industrial environments while using modern industrial connectivity tools.

High-Performance Computing (HPC) for Industrial Use

HPC systems are the new innovation in industrial systems. The integration of AI inference systems and GPU computing power allows the real-time processing of large data sets which is essential for machine vision, edge computing technologies in autonomous vehicles and multi-access edge computing.

As more and more factories start to adapt smart manufacturing methods, high-performance industrial PCs, which function as edge servers, start to analyze data locally instead of sending it to the cloud. This leads to lower response times and improved data security while assisting in missions that require defect detection, quality assurance, and predictive maintenance.

Smart Manufacturing and Edge AI Applications

Industrial PCs are valuable in the smart manufacturing world. In the current smart manufacturing ecosystem, these systems are the hidden power behind the automation, intelligence, and efficiency.

Industrial PCs in Machine Vision Systems

Machine vision systems incorporate cameras, sensors, and AI routines to examine, quantify, and steer industrial operations. The industrial PCs that license the computation needed to interpret high-definition pictures in a fraction of a second are critical in quality auditing and instantaneous decision-making.

Industrial PCs, together with Intel Core processors and specialized GPUs, are able to identify faults, orient parts, and control automation tools with surgical accuracy. This advancement has revolutionized the automotive assembly line, electronics manufacturing, and the production of drugs.

Edge Computing for Autonomous Vehicles and Robotics

The combination of edge computing and industrial PCs is transforming autonomous technologies for various industries. From autonomous mobile robots (AMRs) working in warehouses to completely autonomous self-driving vehicles, edge AI computing and rugged computing provide the power and precision required by these systems.

Edge computing resolves the issue of latency by processing information on the vehicle or robot. This is necessary for real-time decision-making, which is vital for safety and also performance.

Industrial PCs equipped with Intel Alder Lake-N N97 and 12th/13th Gen Intel Core processors, perform complex AI-driven tasks such as path planning and obstacle detection which involves processing sensor, LiDAR, and camera data. In the factory and logistics, rugged embedded computers equipped with RS485, PoE Ethernet, and Wi-Fi perform communications and coordination.

Multi-access edge computing (MEC) is a distributed architecture where multiple network elements work together to enable near real-time processing of data and provide autonomous systems intelligent edge computing. In simple words, industrial edge PCs are the intelligent brain of autonomous systems, making operations faster, safer, and smarter.

HMI Systems in the Food Industry

Food safety and hygiene standards are very demanding computing moisture, high humidity, and rigorous washing and cleaning. This is where industrial panel computers with HMI systems in the food industry succeeds where all traditional PCs fail.

In food processing, beverage production, and cold storage, a panel PC with IP65/IP67 protection works waterproof and resistant. Even with a waterproof panel PC, touchscreen display computers and other waterproof computers are easy to use with gloves on and with wet hands.

Industrial Linux or Windows-based HMIs are connected to temperature, humidity, and production status sensors and PLCs via RS-232 or RS485 and focused on monitoring. Intelligent systems are integrated and utilized made real-time alerts and predictive maintenance while compliance with safety standards is improved.

In food inspection and logistics, rugged tablet computers facilitate on-site reporting and rapid quality checks, thereby streamlining processes. It is clear that industrial PCs provide precision, unswerving performance, and operational hygiene that bolster food manufacturers’ productivity in the fulfillment of quality standards. Every production cycle must maintain the consistent quality of the output.

Smart Manufacturing and IoT Integration

Smart manufacturing is driven through the collaboration of industrial PCs and IoT technology. The integration of computers, sensors, and machines provides a new level of real-time monitoring and control. Embedded computers and industrial panel PCs serve as intelligent gateways and connect legacy devices to modern cloud and edge platforms.

Predictive maintenance, process optimization, and seamless factory integration are achieved through a fanless panel PC equipped with Intel J6412, PoE Ethernet, and RS-485. AI computers and edge servers facilitate instant decision-making and streamlined processes through local data processing to minimize latency.

Having this kind of connectivity allows operators to monitor key performance indicators (KPIs) across the globe, including the consumption of energy, the usage of equipment, and the overall health of equipment. This makes the environment of self-learning and adaptive manufacturing more efficient, intelligent, and in the core of digital transformation.

The Role of Industrial PCs in Machine Vision and Quality Control

Machine vision involves the use of industrial PCs, facilitating the real-time inspection of products, and the detection and identification of product defects. This is done with a large degree of precision and accuracy. By applying high-speed digital cameras and utilizing AI for image processing, flaws are automatically detected and evaluated in seconds, which is a much faster and efficient process than human inspection.

HPC industrial PCs with Intel Core processors are able to analyze and process multiple high-resolution video streams in real-time for a variety of industries which include electronics, automotive, and packaging. Industrial touch screen monitors provide immediate feedback and IoT enables the integration of data and feedback for trend analysis. i.e. industrial computers, like industrial linux computers.

Edge Servers: The Backbone of Smart Factories

Edge servers are the central and main processing hubs of smart factories. They connect and offer communication to numerous industrial PCs, numerous sensors, and a variety of devices. The process of edge computing allows for the real-time automation of processes by limiting latency, increasing security, and processing data locally.

These systems, which are based on Intel’s Alder Lake-N N97 and 6th, 7th Gen Intel Core processors, are fanless and equipped with PoE ethernet, RS232, and RS485 ports, which allows them to provide uninterrupted performance. Rather than waiting to process and analyze data, edge servers integrated with machine vision, robotic arms, and IoT devices provide instantaneous data analysis and even predict failures before they happen. This drives efficiency, scalability, and reliability for the modern Industry 4.0 environments for reliability.

Rugged Computing Beyond the Factory Floor

Industrial PCs are utilized in harsher environments, like mining, construction, and the oil and gas industry, which are even tougher than a factory. Rugged laptops and handheld computers even meet military specifications for drop, vibration, and extreme cold and heat testing.

Field engineers need portable, water resistant rugged tablets and laptops with RS485 and RS232 ports, PoE ethernet, and industrial Linux, which provide a stable, low power solution for control and real-time data in remote areas, to provide control and real-time data in remote areas. From asset tracking to control on machines, rugged computing technology permits continuous recording, correcting, and decision making to automated systems in extreme environments.

Future Trends: AI and Edge Intelligence in Industrial PCs

Automation and smart manufacturing adoption is seeing a new wave of advancements with AI-integrated industrial PCs that combine AI with edge computing and the Internet of Things (IoT). With Edge AI and Intel Core and Alder Lake-N N97 processors onboard deep learning tasks are performed on-site, markedly increasing speed, security and efficiency.

From machine vision that detects and analyzes payloads to autonomous robots that streamline work processes, AI Edge PCs are enabling tremendously advanced, intelligent operations. Factories are becoming self-learning ecosystems with multi-access edge computing (MEC) and smart panels with real-time AI built-in analytics. Truly revolutionary AI will take the form hybrid systems that not only streamline processes, but will automate, adapt, and polish a manufacturing unit in real time.

Selecting the Right Industrial PC for Your Application

When selecting the right industrial PC, your environment and performance specifications will dictate the best option. In dusty or wet work conditions, the best option is a waterproof panel PC or a water resistant computer with IP65/IP67 protection. For external work environments, the best choice would be outdoor panels that are high bright and temperature tolerant.

For basic control tasks, a fanless embedded computer with Intel Celeron J1900 or J6412 works well, but for advanced AI and machine vision applications, processors with higher capacities like Intel Alder Lake-N N97 or 12th/13th Gen Intel Core are essential.

Please check that your system has RS232, RS485, and PoE Ethernet ports so that you can easily connect the new and the old equipment. If you need to be more mobile, fully rugged laptops and rugged tablets can meet the required ruggedness and performance in the field.

For stability and security over time, select units with industrial offering Linux or Windows IoT. Working with a reputable vendor like GDCompt.com will provide you with appropriate system advice, personalized configuration, and reliable support after the sale.

Why Industrial Personal Computers Are the Foundation of Smart Manufacturing

These computers allow the system to function in demanding environments while successfully working with AI and IoT systems. They enable intelligent and precise operation of production facilities through real-time processing of data and performance control via machine vision, autonomous robots, and edge servers.

Whether you need fanless panel PCs or mobile, robust notebooks, you will get sophisticated processing power for task performance. As industrial PCs progress with edge AI and intelligent panels, they will continue to make the connection between the physical and the digital, ultimate driving automation and innovation for the Industry 4.0 revolution.

Conclusion

Industrial PCs are changing the game when it comes to smart factories and edge AI manufacturing. From waterproof panel PCs to rugged tablets and edge servers, these systems are powerful and transformative. Designed to function where traditional computers would cease to operate, state-of-the-art industrial PCs constructed with the Intel J6412, Alder Lake-N N97, as well as 12th and 13th Gen Intel Core processors provide extraordinary speed, trustworthiness, and brilliance. Industrial PCs are essential to machine vision, autonomous vehicles, HMI systems, and much more, supporting the smart, interconnected factories of the present.

FAQs

1. What is the main difference between an industrial PC and a regular PC?

The production of industrial PCs incorporates requirements fundamental to the belief of durability, stability, and continuous functioning when exposed to harsh conditions. Differently to a standard PC, it utilizes a fanless cooling system i.e. solid-state components and rugged encasements that resist dust, vibration, and moisture.

2. Why are fanless panel PCs popular in manufacturing?

Dust ingestion and mechanical wear are prevented by the use of fanless panel PCs, diminishing the frequency of required servicing. Their enlisted operational noise and sealed designs make them exceptional for cleanrooms, food processing, and automation environments.

3. How does edge computing benefit smart factories?

Instead of sending data to the cloud, edge computing allows for data to be processed on-site. This reduction of latency boosts security and allows for real-time, AI-powered decision making to happen instantly.

4. Which processors are best for industrial PCs?

For routine automation assignments, the Intel Celeron J1900 or J6412 processors are dependable options. For AI and more demanding tasks, the preferred options are the Intel Alder Lake-N N97 or the 12th and 13th Gen Intel Core processors.

5. Do industrial PCs support AI and machine vision?

Of course. Current AI computers and HPC industrial systems are capable of executing deep learning models and performing machine vision tasks such as defect detection, automation control, and predictive maintenance.

Penny

Web Content Writer

4 years of experience

This article is edited by Penny, the website content writer of COMPT, who has 4 years working experience in the industrial PCs industry and often discusses with colleagues in R&D, marketing and production departments about the professional knowledge and application of industrial controllers, and has a deep understanding of the industry and products.

Please feel free to contact me to discuss more about industrial controllers. sales@gdcompt.com